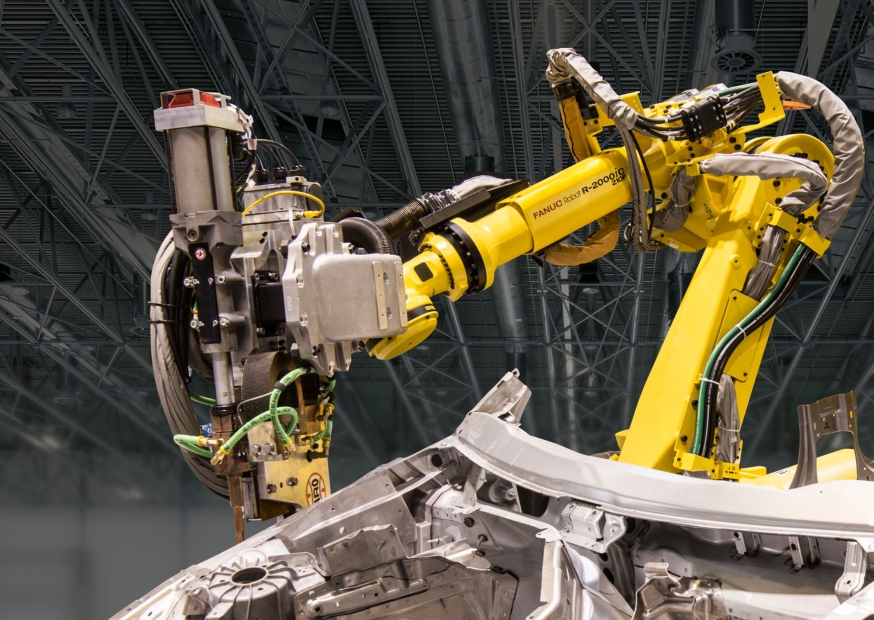

Robotic arms have revolutionized manufacturing, mixing safety, precision effectiveness, and other aspects that were previously impossible. Robots are amazing mechanical devices that are now essential to all industries across the globe. They were created to reduce operating costs and keep high standards of quality. Integrating robotic arms into production lines allows manufacturers to not only reduce expenses but also improve worker safety and efficiency. We’ll investigate how these groundbreaking machines are changing the landscape of industrial production.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. Factories face relentless pressure to cut down on production errors, reduce material waste, and lower workplace accident rates. Robotic arms are specifically designed to address these issues. Robot arms are more accurate than humans when it comes to performing repetitive tasks, thus reducing the amount of waste and avoiding costly mistakes. For high-volume industries, like automotive manufacturing, robotic arms ensure perfect assembly through precise welding and part placement. This accuracy results in substantial savings, as less defects will mean less rework, wasted and work.

Safety is the second main element in the emergence of robot arms. Numerous manufacturing tasks, like handling dangerous materials or using heavy machinery could be hazardous for human workers. Utilizing robot arms, businesses can remove workers from hazardous environments. This decreases the chance of injury at work. Robotic arms consist of a variety of movable joints that mimic human arm’s capabilities. However, they operate with no danger of injuries. Equipped with end effectors that can be programmed to work essentially robotic hands these machines can handle tasks like grabbing, spinning or welding in situations which are dangerous for humans.

Robotic arms’ versatility can be a game changer in different industries. From automotive assembly to electronics production, robots can adapt to a wide range of tasks. The ability to program these arms enables them to carry out difficult tasks such as painting or applying fiberglass at an unmatched quality of consistency. Robotic arms used in warehousing has revolutionized palletizing by automating the process of loading products onto pallets. Automation does not just increase efficiency, but also reliability as robot arms are able to operate without a lot of fatigue.

Cobots are the latest breed of robots able to work in tandem with humans. Cobots with robotic arms, unlike industrial robots which are isolated in cells, are designed to interact with human beings safely and smoothly. The hands of a robot is able to do routine tasks like heavy lifting in factories, ensuring that workers can be freed up to handle more complex tasks. Collaboration increases productivity, while ensuring a safe work space, since cobots are programmed to stop or adjust their movements if a human is nearby.

The significance of robotic arms goes beyond safety and efficiency, to the fundamental structure of modern manufacturing. The ability of robotic arms to accomplish tasks that require precision, such as welding, material handling or assembly is what makes them essential in fields that place safety first. For automotive production, for example, a robot arm can rotate and place parts during assembly for perfect alignment without the need for human intervention. Robots are also utilized in electronics to care for fragile components. This reduces damage, and enhances output quality.

As the world’s industries continue to develop robots’ roles will grow. They will be a key element in the future of manufacturing due to their capability to cut costs, increase safety and adapt to different tasks. Through the combination of cutting-edge technology and human innovation Robot arms are not just tools. They are partners in progress, driving innovation and revolutionizing the way we create our world.